WIND HUNTER Green hydrogen producing vessel

WIND HUNTER Project ~Shape the future with wind and hydrogen~

With the passing of time, the energy for ships’ propulsion changed from manpower and wind power to steam turbine powered by coal and then to diesel engines powered by petroleum. Today, maritime transport accounts for more than 99.5% of the world’s international trading (by tonnage, as of 2021), and the massive consumption of fossil fuels by ships is impacting global warming.

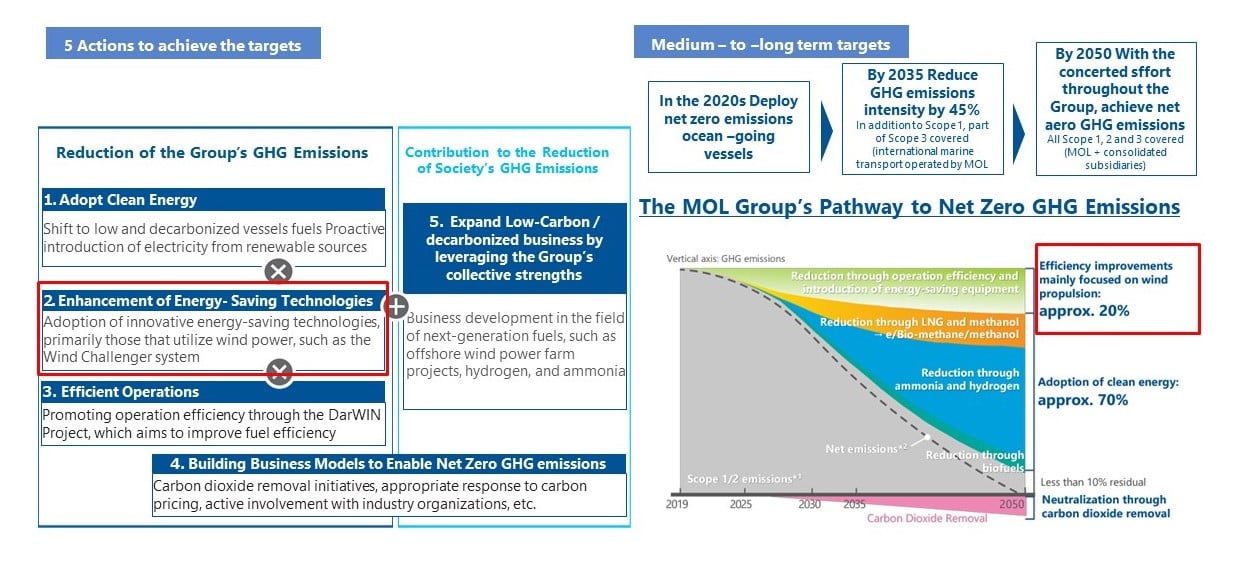

In 2018, the International Maritime Organization (IMO) set a target to reduce GHG emissions from ships by at least 50% from the 2008 level by 2050, but in 2023, the IMO resolved to raise this target significantly and set a new target to achieve virtually zero GHG emissions by 2050. In 2021, prior to the resolution in 2023, MOL group set a target of achieving net-zero emissions by 2050 and is engaged in a variety of research and development activities.

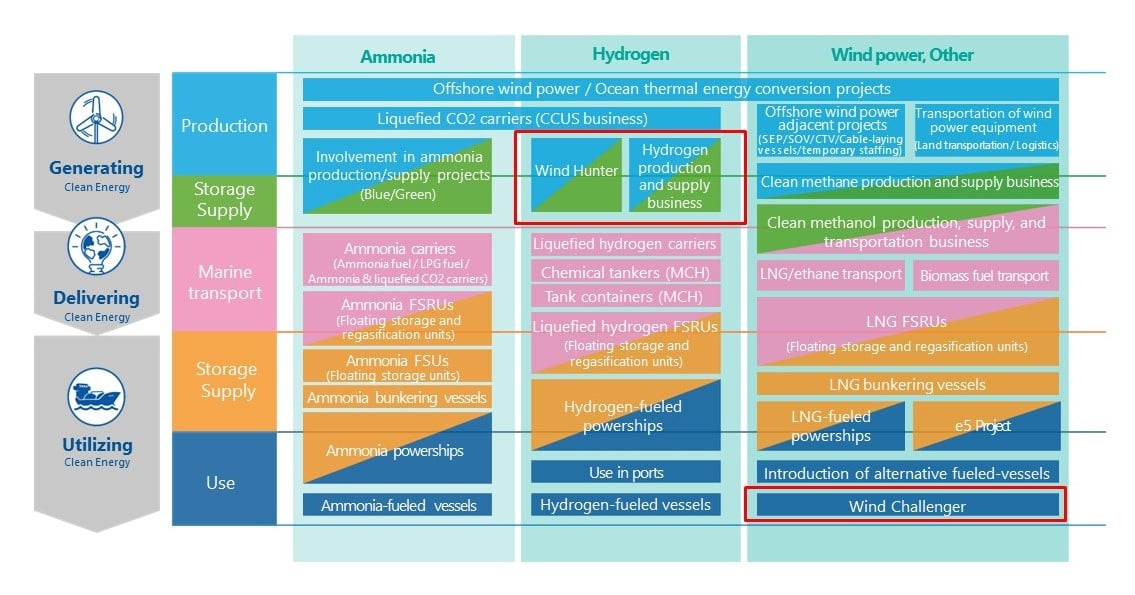

Overview of Ocean Clean Energy Business

MOL has established MOL Group Environmental Vision 2.2 and has already taken steps to reduce GHG emissions. In 2022, SHOFU MARU, a ship equipped with Wind Challenger sails which use wind as auxiliary propulsion, was delivered and started her operation.

Wind Challenger sails are state-of-the-art “rigid sails” covered with FRP (Fiber Reinforced Plastic), hard material and can efficiently convert wind power into propulsion.

The ratio of fuel consumption reduction is depended on the wind direction and wind force on the vessel's route, it can reduce fuel consumption by 5-8% in average.

GHG Reduction and Ship Fuel Composition Scenarios

As a key action towards achieving substantial net zero greenhouse gas (GHG)emissions by 2050 and promoting sustainable development for people, society and the planet, MOL aims to achieve the "Green Ocean Shift" by contributing to construct clean energy supply chain from upstream to downstream.

WIND HUNTER

~Green hydrogen production plant on the sea~

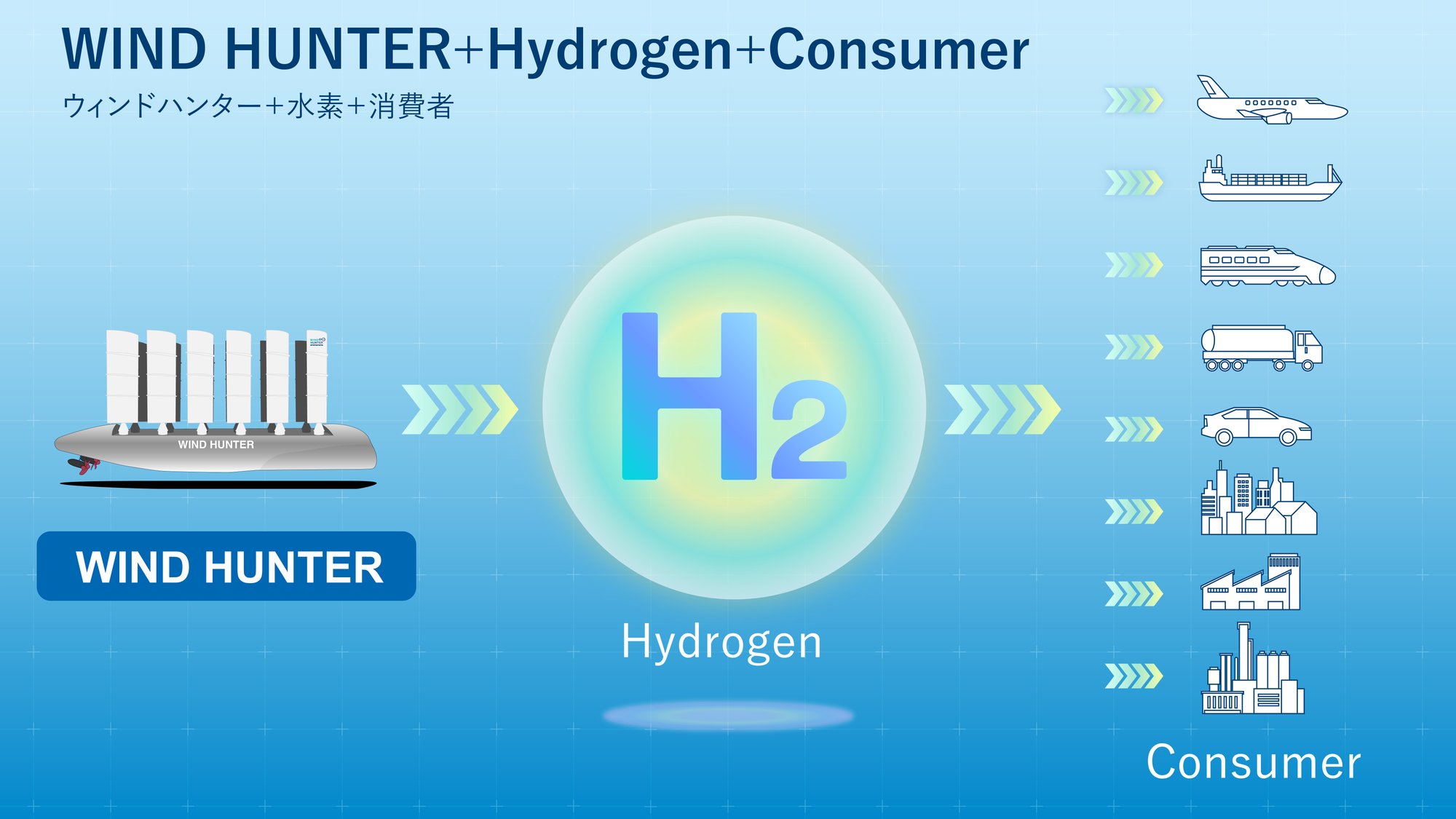

WIND HUNTER, it is a vessel which aims to leverage the sail technology that MOL nurtured in Wind Challenger project and applies more advanced technology to create, store, and transport green hydrogen produced by infinite offshore wind. In other words, it is a hybrid plant that combines a moving offshore wind turbine and a hydrogen production facility.

WIND HUNTER does not use fossil fuels at all for propulsion but use hydrogen that is created and stored by the ship itself. The project also aims to supply the hydrogen energy to the land usages, and to achieve complete zero emissions.

Producing Hydrogen

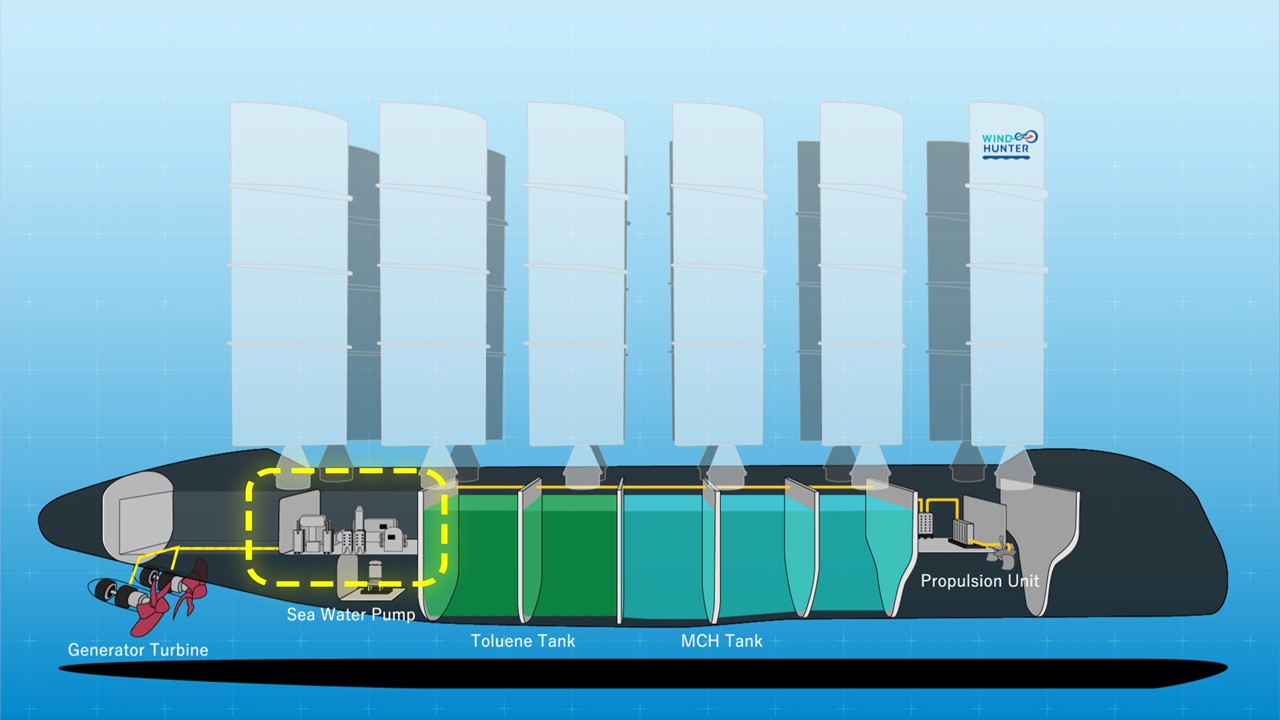

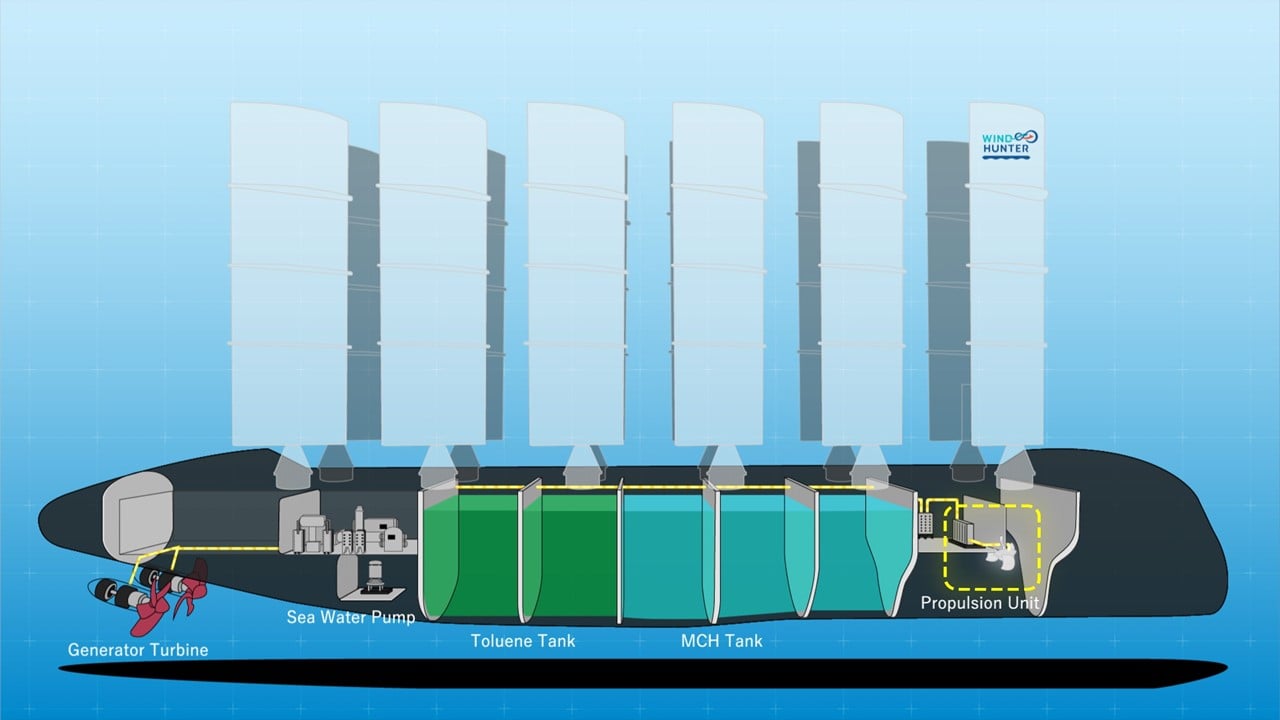

The Wind Hunter cruises using wind energy, while at the same time generating electricity by underwater turbines. By electrolyzing pure water made from seawater, it produces hydrogen.

By causing a chemical reaction of hydrogen and toluene, it creates Methylcyclohexane: MCH, which is one of the hydrogen carriers, and stores that in MCH tanks onboard.

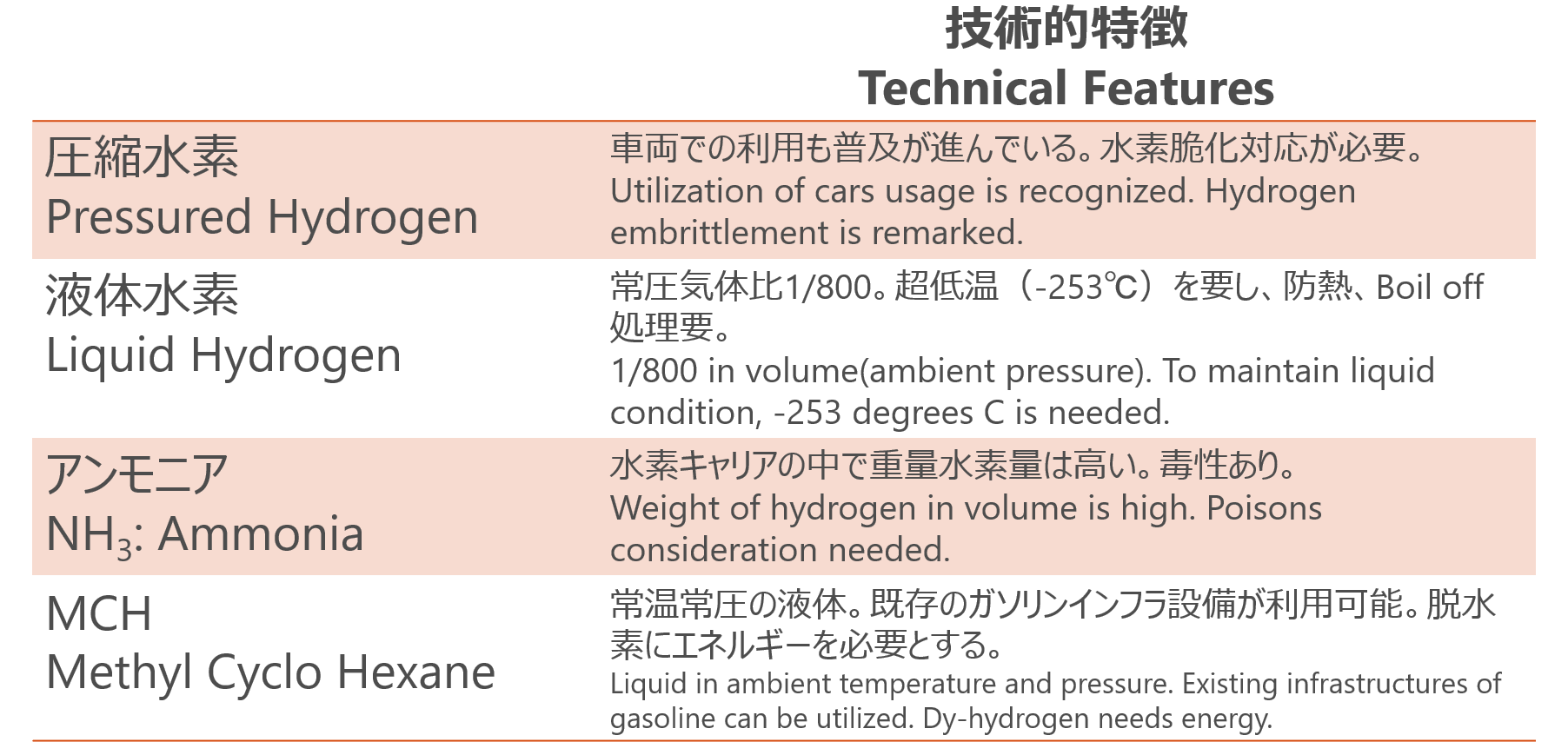

What’s the advantages of MCH?

Hydrogen generated onboard is gas condition. To store hydrogen energy effectively and safely, various carries can be exited. One of the solution would be liquid hydrogen, which requires higher level of safety due to its cryogenic conditions. It is very important to convert hydrogen into safer using the least amount of energy.

MCH, a hydrogen carrier, has the following features and does not require expensive equipment.

(1) Easy to handle because it is liquid at ambient temperature and pressure.

(2) Efficient and safe for storage and transportation of hydrogen

Hydrogen, as fuel for ships

For the first time in the world, MOL has succeeded to propel a ship by hydrogen which was dehydrogenated from MCH.

Demonstration by the yacht "Winz Maru" (2’41”): https://www.youtube.com/watch?v=5OajytKJV5Q

Related Press Release: https://www.mol.co.jp/pr/2021/21112.html

.jpg?width=2000&height=1125&name=06_MCH%20(1).jpg)

While Wind Hunter can proceed by offshore wind power, the rigid sails are extended and hydrogen is produced.

In low/still wind areas, the sails are shrunk and Wind Hunter proceeds by rotating propulsion propeller powered by electricity. Hydrogen is extracted from the stored MCH and electricity is generated by the fuel cells powered by hydrogen.

Deliver Hydrogen

Before the vessel approaches to the port, all sails are shrunk and the vessel proceeds by propulsion propellers.

Once the vessel has safely berthed, to discharge MCH, drones help to connect the manifold of the vessel and the loading arm on land.

After the discharging operation is completed, toluene is replenished the ship towards next voyage.

Utilize hydrogen

WIND HUNTER an option “unmanned solution” in the future, can be sail and supply energy not only to nearby ports in large cities but also to rural areas and remote islands, taking advantage of the ship as a mobility advantage. This technology enables the production and supply of hydrogen using ships at locations where hydrogen is in demand.

MOL aims create hydrogen supply chains to employ such technologies and would need further collaborations with various parties and stakeholders to achieve strong enough for the future.

From Imagination to Creation, MOL is taking on the challenge of realizing WIND HUNTER.