Wind Challenger

As worldwide calls for carbon neutrality increase, the shipping industry is facing the need to reduce its greenhouse gases (GHG) emissions. MOL has cast a spotlight on the potential of wind power as a clean and unlimited source of energy, and has developed the Wind Challenger. Wind Challenger is an innovative solution to reducing GHG emissions which uses state-of-the-art and proprietary technologies that sense wind direction and speed in real time and provides fully automatic control of sail extension, contraction, and rotation.

Using this method, we completed construction of the 100,000-DWT coal carrier SHOFU MARU equipped with the Wind Challenger in October 2022. In the approximately 18 months through April 2024, the ship transported coal on a total of seven round-trip voyages to Japan, mainly from Australia, Indonesia, and North America, with reduced daily fuel consumption by up to 17%, equating to 5% to 8% per voyage on average.

What is a Wind Assisted Ship Propulsion System?

A wind assisted ship propulsion system is a device that assists the propulsion of a ship using the power of wind. Wind is a renewable energy source that incurs no cost and is inexhaustible, and by harnessing its power, we can reduce GHG emissions and fuel consumption.

Anticipated Functions and Benefits of Wind Assisted Ship Propulsion Systems

Wind assisted ship propulsion systems are expected to offer the following three main functions and benefits.

1. Contributing to Fuel Savings and Decarbonization

In July 2023, the International Maritime Organization (IMO), the global standard-setting authority of the United Nations, revised the IMO GHG Strategy which had been adopted in 2018, agreeing on a goal of net-zero GHG emissions from ships by around 2050. In response to this announcement, shipping operators have begun incrementally switching from fossil fuels to zero-emission fuels.

Wind assisted ship propulsion systems are expected to help achieve the goals laid out by the IMO through fuel savings and reductions in GHG achieved through wind assisted operations.

2. Safety and Quality

High levels of safety are required in the operation of ships, for which strict international standards and regulations have been established. Ships equipped with wind assisted ship propulsion systems must not only reach their destinations safely, but the systems must also be manufactured with reliable technologies and function without any issues, and their structure must be robust enough to withstand severe weather and resist breakdowns.

3. Usability

In contributing to decarbonization, ease of operability is another important factor for wind assisted ship propulsion systems. The systems must be compatible with various types of ships from dry bulk carriers to tankers and LNG carriers, both newly-built and existing ones, and must not significantly affect the amount of cargo being carried. It is also crucial that the system does not require specialized skills and can be easily operated, managed, and maintained by general crew members.

MOL’s Wind Challenger: The Latest Wind Assisted Ship Propulsion System

The Wind Challenger is a wind assisted ship propulsion system for hard sail* systems developed by Mitsui O.S.K. Lines, Ltd. It utilizes the renewable energy of wind power to propel ships using sails.

Large commercial vessels today rely almost solely on fossil fuels for their propulsion. The Wind Challenger adds wind power directly to a vessel’s propulsion force by installing sails, reducing the consumption of fossil fuels without changing the vessel’s speed. By installing and effectively utilizing sailing vessel techniques from the past and evolving them as much as possible by leveraging the latest technologies, large cargo vessels can reduce fuel consumption and dramatically cut their GHG emissions.

- Hard sail: A stiff wing-shaped sail that does not change shape.

Wind Challenger Functions and Features

MOL developed its Wind Challenger using the latest technologies. Here we will explain its features and functions in seven different areas.

1.Maximizes Propulsion by Harnessing Wind Power, Contributing to Decarbonization

The sails have been made lighter in weight to stabilize the ship by reducing load, while broadening the effective wind direction range by fine-tuning the shape of the sail’s cross section, all of which serves to maximize the use of wind as a propulsion force.

From its inception, the Wind Challenger was developed and implemented with a vision of the single operation of three factors: the sails, the control system, and weather routing (optimum ship routing system). The weather routing system aims to further improve fuel efficiency by proposing the optimum route for the ship.

The SHOFU MARU, the first ship equipped with the system to complete its maiden voyage, recorded fuel consumption reductions of 5% on the Japan-Australia route and 8% on the Japan-North America West Coast route, with up to 17% per day fuel consumption reduction when the sails were operated in automatic control mode, according to data collected from the ship. Equipment improvements are currently under way based on the performance results of the SHOFU MARU.

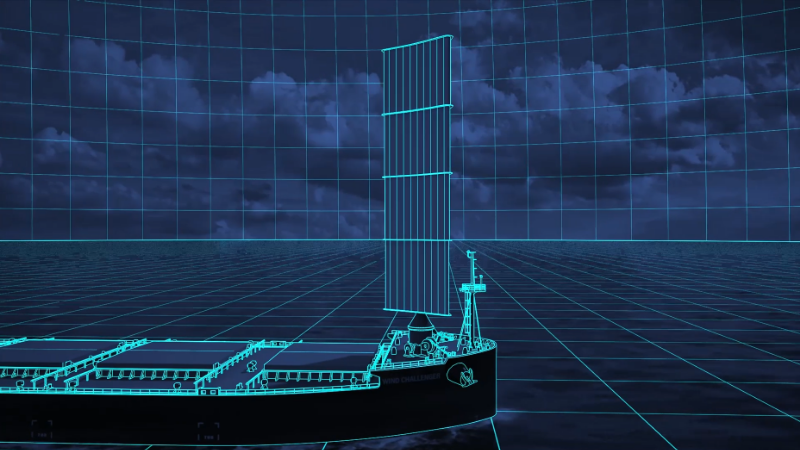

2.Weight Reduction and Telescopic Function

It is crucial that sails be light enough so that the wind assisted ship propulsion system does not impact the amount of cargo that ships can carry. The sails for the Wind Challenger use surface materials made of glass fiber reinforced plastic (GFRP), not typically used as structural material on ships, to reduce sail weight.

In addition, the sails can be extended and retracted to lower the center of gravity and keep the ship stable when weather is rough. This ensures the same level of safety with commercial vessels as with ordinary vessels without sails.

3.Compatible with Various Types of Vessels

The Wind Challenger can be fitted on both newly-constructed and existing ships. It does not interfere with existing energy-efficiency devices below the waterline and can be implemented on a wide range of vessels, from bulk carriers (dry bulk ships) to tankers and LNG carriers, and can be installed multiple times.

The second bulk carrier equipped with the Wind Challenger, which was completed in July 2024. MOL Group company MOL Drybulk Ltd. will operate this new vessel. This vessel is smaller than the SHOFU MARU with a cargo weight of 64,000 DWT, but it employs greater use of fiber reinforced plastic (FRP), and there are plans to convert its telescopic drive mechanism from hydraulic to electric. It was determined in May 2024 that the system would be installed on seven newbuilding bulk carriers and multi-purpose vessels operated by our group company MOL Drybulk.

4.Ensuring Safe Navigation in Any Weather Conditions

Safety is an essential element for wind assisted ship propulsion systems. The Wind Challenger has a structure that is lightweight, so it does not impair the vessel’s balance, ensuring safety during navigation.

What is more, operators can choose between maximum lift angle to maximize wind power or zero lift angle that minimizes wind resistance in rough weather, ensuring safe operation in any weather conditions.

5.Auto-Control System that All Crew Members Can Operate

Normally, the sails on sail vessels must be adjusted in direction and tension according to the strength and direction of the wind, requiring operators to have high levels of knowledge and experience. The Wind Challenger employs a control system that is fully automated, enabling crew members to maximize the use of the wind easily, without any special skills being required. The Wind Challenger has proprietary technology that uses sensors to detect the speed and direction of the wind, and automatically extends, reduces, and rotates the sail.

6.Ease of Maintenance

Like other kinds of general machinery, the mechanical components at the base of the hard sail, such as the hydraulic pumps for sail expansion and contraction and the swivel motors used for rotation, require maintenance based on operating hours.

The steel parts of the sail are protected by paint, but they will be re-painted at a dock if rusting becomes an issue over the years. The FRP components are basically maintenance-free, although we believe they will require re-painting after a certain period of time to maintain their visual appeal as their colors fade with exposure to ultraviolet light.

In our development of the Wind Challenger, we plan to incorporate various kinds of feedback and provide conscientious updates that improve usability, performance, and maintainability.

7.Produced with Reliable Technologies that have Supported the Shipping Industry for Years

Since its founding over 140 years ago, MOL has contributed to marine transportation throughout the world. Oshima Shipbuilding Co., Ltd. has been manufacturing vessels for shipping companies in 27 countries, including Japan, for over 50 years. The combination of these two firms’ dependable technologies lie at the center of the manufacturing and development of Wind Challenger. Learning from past examples of sail vessels, the Wind Challenger features a zero lift angle and a telescopic system, making it a wind assisted ship propulsion system that draws on a combination of existing technologies.

Steps for Installing the Wind Challenger

When implementing Wind Challenger, we first ask customers about the type of vessel and ports of call where the Wind Challenger will be used to best respond to their needs, then propose the most suitable vessel specifications.

To achieve its target of net-zero GHG emissions by 2050, MOL plans to deploy 25 vessels equipped with Wind Challenger technology by 2030 and 80 vessels by 2035. We have accumulated operational expertise through the safe management and efficient operation of our fleet of eco-friendly vessels that use both the Wind Challenger and other wind assisted ship propulsion technologies, and we will further advance these technologies and utilize renewable energy while ensuring safety to contribute to GHG emissions reductions by our group to the benefit of all society.

Related Press Releases

- May 27, 2025

- Apr 10, 2025

- Sep 13, 2024

Download and Consultation

Wind Challenger Service Overview

download materials about outlines the Wind Challenger, including its structure and how it is propelled by wind.

Inquiry(Wind Challenger)

Please feel free to contact us about our Wind Challenger and associated services.

-

About services

-

Customization

-

Schedule

-

Quote

-

Support

-

Other

Related Case Studies

-

Delivered the first Wind Challenger

Wind ChallengerMitsui O.S.K. Lines, Ltd. (MOL) has developed the Wind Challenger, which converts wind energy directly to a vessel propulsion force. As a part of this project, the hard sail system to be installed on the first Wind Challenger ship was finally completed in February 2022.

-

Sea Trial for Wind Challenger Project

Wind ChallengerMitsui O.S.K. Lines, Ltd. (MOL) has developed the Wind Challenger, which converts wind energy directly to a vessel propulsion force. As a part of this project, the hard sail system to be installed on the first Wind Challenger ship was finally completed in February 2022.

-

Hard Sail Completed for Wind Challenger Project

Wind ChallengerThe hard sail system to be installed on the first Wind Challenger ship was finally completed.

-

DELIVERY OF 1ST WIND CHALLENGER

Wind ChallengerAs part of our greenhouse gas (GHG) emission reduction project, the first Wind Challenger is scheduled for completion.

Related Solutions

WIND HUNTER

This is an ultimate zero emission project under the Wind Challenger Project, currently in progress with MOL.

Offshore wind energy from sails is used not only as a propulsive force for the vessels, but also for the generation of hydrogen. We are studying ways to supply hydrogen to users on shore by combining this system with fuel cell, etc.

Related Contents

Contact

- Top

- ENERGY SAVING TECHNOLOGY

- Wind Challenger:The Wind Assisted Ship Propulsion System