Advanced Support Technologies for Safer Vessel Operation

FOCUS

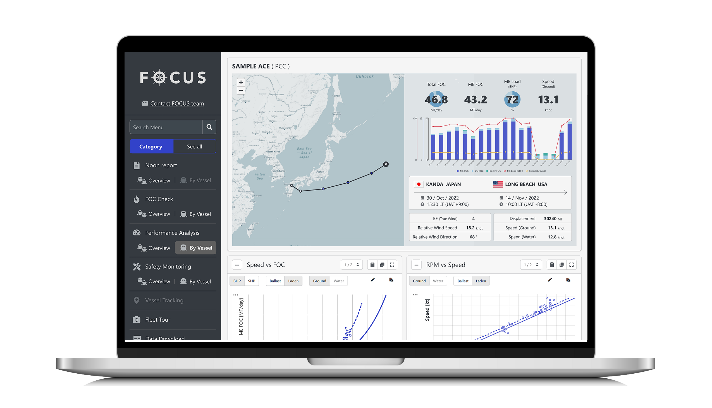

FOCUS sets a new standard in enhancing vessel safety, environmental protection, and commerce with the power of onboard data to realize the next generation of maritime digital transformation (DX).

A New Standard for Ship Operations - FOCUS

FOCUS is an integrated system of up to 10,000 sensor data points per vessel, collected from about 270 vessels and reporting information from about 650 vessels in total. In addition, the onboard application incorporates MOL's decades of accumulated operational know-how as a multimodal transport group into its analysis technology.

FOCUS is driving the digital transformation of the ocean shipping industry by providing functions that meet the needs of diverse ship types and maritime stakeholders, and supporting more efficient ship operations and improved environmental protection. We contribute to the development of the shipping industry by providing value to a wide range of stakeholders, including shipowners, operators, and ship management companies.

System Overview

FOCUS Data Platform

To operate vessels safely and reduce their environmental impact, we are building a system that collects and manages detailed navigational and engine data obtained from vessels operating at sea. The system will enable advanced monitoring of vessel operations and more precise analysis of propulsion performance.

Data Flow

FOCUS uses the following procedures to collect and utilize data.

- Data Collection: Data from IoT devices installed on vessels and wharves is collected through Fleet Transfer, Voltage Data Recorder (VDR), data loggers, integrated automation system (IAS), and other sensors.

- Send: The collected data is sent to the Amazon Cloud database.

- Store: Stored data will be accessible from devices such as PCs, smartphones, and tablets.

- Utilization (Application): Collected data is utilized through various applications such as automatic emailing, engine and machinery monitoring, and generation of Noon Report data. It also provides functions such as analyzing speed performance and monitoring Noon Report data.

Through this process, FOCUS aims to improve the efficiency and safety of vessel operations and reduce environmental impact. The sequence from data collection to utilization is an important platform for the shipping industry's digital transformation.

FOCUS in Action

Determining the vessel’s propulsion performance

FOCUS analyzes the propulsive performance of the vessel based on the collected operational data.

It makes the relationship between a vessel's fuel consumption and speed visible at a glance, and is applied to formulate optimal operation and repair plans.

Assessment of propulsion performance before and after the measures

When energy-saving devices are installed and hull surfaces are cleaned, we can quickly verify the effectiveness of the measures by collecting and utilizing ship operation data from Fleet Transfer at intervals of up to one second, and analyzing speed controllers before and after the measures. This will streamline the assessment of various measures, and we swiftly expand these measures to other vessels across the fleet.

Assessing the degree of biofouling on hull surfaces

Marine organisms on the hull surface increase drag on the ship and reduces the speed that can be achieved with the same main engine output. FOCUS supports optimal maintenance and prevents unnecessary fuel consumption by monitoring a time series of vessel speed reductions, an indicator of biofouling.

Data shows main engine status

Signs of various problems can be identified from the high-frequency sensor data collected from each device. In one case, a broken piston ring was discovered when unnaturally elevated exhaust gas temperature and scavenging air temperature of the main engine prompted an inspection of the piston. Capabilities like this help reduce downtime due to equipment failure on vessels by providing an in-depth look at the condition of machinery and equipment.

MOL FOCUS Case Study

Application of FOCUS to achieve MOL Group Environmental Vision

MOL relies on FOCUS to achieve one of the targets in its environmental vision: Improve fuel efficiency by 5% as of 2025 compared to 2019. This target is intended to realize more sustainable operations by reducing fuel consumption and CO2 emissions. FOCUS makes it possible to analyze vessel operation data and identify points for improvement in fuel efficiency. In this way, MOL is committed to improving operational efficiency while reducing its impact on the environment.

FOCUS×DarWIN

The DarWIN project promotes more efficient operations and energy-saving devices, aiming to reduce GHG emissions.

Each division's efficiency operation project is designed to be intuitive and easy to understand, and the effects of fuel reductions due to the introduction of energy conservation measures can be tracked in time series. Furthermore, monthly reports on progress and results are distributed to the relevant divisions, promoting the projects aimed at achieving the set targets. This process enhances efficiency and energy conservation efforts throughout the organization to ensure more sustainable operation.

*The above figure is for illustration purposes only and may differ from the actual values.

Monitoring at the Marine Safety Division

FOCUS’s high-frequency collection of sensor data allows us to quickly grasp the status of vessel equipment, and analyze the collected data to automatically identify vessels that are most likely to experience problems.

The Marine Safety Division monitors the status of vessels as determined by FOCUS and checks for any abnormalities. We also share information with ship management companies to strengthen cooperation on securing vessel safety. This process allows for early detection and response to problems that may arise during vessel operations.

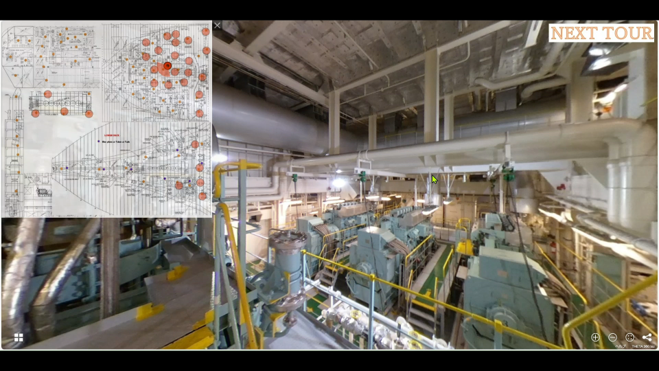

“Fleet Tour” offers a new ship management experience

“Fleet Tour” is a virtual ship inspection application that adopts Ricoh Co., Ltd.'s 360-degree Ricoh THETA camera and virtual tour creation service THETA 360.biz.

“Fleet Tour” allows ship management companies and operators to view 360-degree images and videos of various areas of the vessel from PCs and smartphones, creating a virtual visit experience that allows them to intuitively grasp conditions in various onboard locations. In addition, “Fleet Tour” solves issues facing land-based employees such as the sheer size of vessels —some more than 300 meters long—which limits opportunities to inspect the entire vessel in a limited time; plus, it is difficult to intuitively comprehend a vessel’s structure from drawings or conventional plan photos.

Certification Results

Certification Results

FOCUS has obtained Innovation Endorsement (IE) certification from Nippon Kaiji Kyokai (ClassNK).

IE Certification is a framework for supporting innovative initiatives through third-party certification, and FOCUS’s advanced data application examples and contribution to safe and environmentally friendly operations were highly evaluated as innovative initiatives.

Download

FOCUS Service Overview

Download service materials overviewing FOCUS, the new standard of ship operation.

Related Press Releases

- September 26, 2024

- August 04, 2020

- February 21, 2020

- October 15, 2018

Related Contents

Contact

- Top

- ENERGY SAVING TECHNOLOGY / SMART NAVGATION

- FOCUS (Fleet Optimal Control Unified System)