WIND HUNTER

Green hydrogen production/supply vessel

Learn about Mitsui O.S.K. Lines, Ltd.'s project to achieve zero greenhouse gas emissions and build a hydrogen supply chain around the world by utilizing the "Wind Hunter," a green hydrogen production/supply vessel that uses offshore wind power to produce, store, and transport hydrogen.

Mitsui O.S.K. Lines, Ltd. Wind Hunter Project Key Points

- This project uses Wind Hunter, a green hydrogen production/supply vessel that can produce, store, and transport hydrogen while sailing using offshore wind power, to achieve complete zero emissions.

- Wind Hunter utilizes MOL's "Wind Challenger" technology.

- Hydrogen can be produced and stored by moving to a location where wind conditions are favorable. The green energy, stored in battery while it is stored during turbine generation at windy period, is used to propel the vessel with electric propellers during less/no wind.

- The goal is to establish a worldwide hydrogen supply chain by supplying hydrogen produced by Wind Hunter to places wherever it is needed.

WIND HUNTER Project

~Shape the future with wind and hydrogen~

With the passing of time, the energy for ships’ propulsion changed from manpower and wind power to steam turbine powered by coal and then to diesel engines powered by petroleum. Today, maritime transport accounts for more than 99.5% of the world’s international trading (by tonnage, as of 2021), and the massive consumption of fossil fuels by ships is impacting global warming.

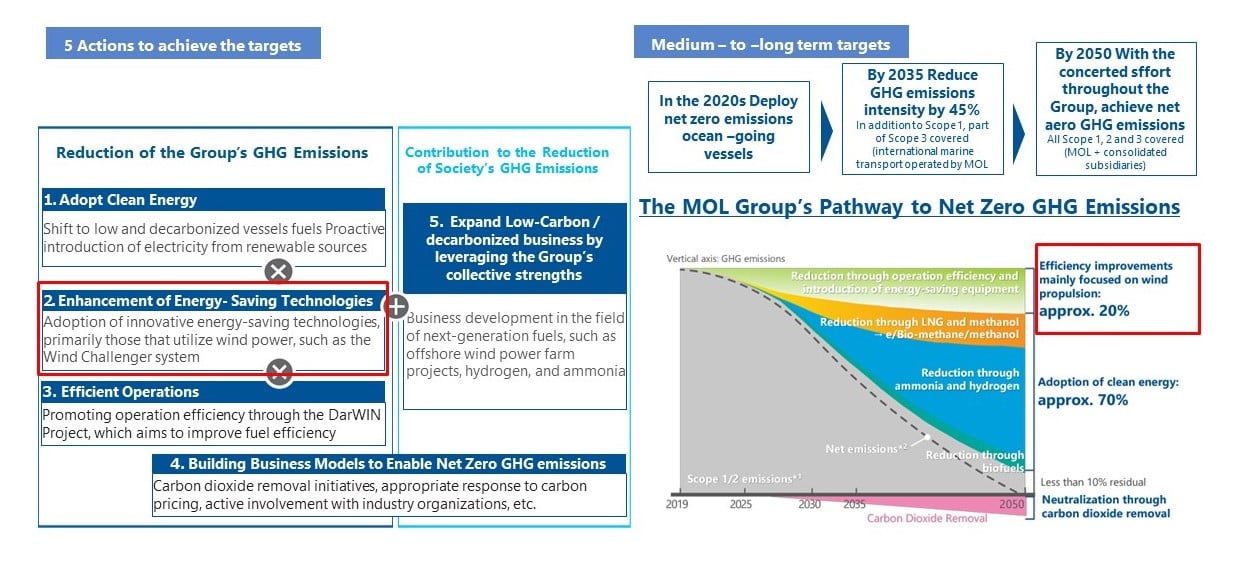

In 2018,the International Maritime Organization (IMO)set a target to reduce GHG emissions from ships by at least 50% from the 2008 level by 2050, but in 2023, the IMO resolved to raise this target significantly and set a new target to achieve virtually zero GHG emissions by 2050. In 2021, prior to the resolution in 2023, MOL group set a target of achieving net-zero emissions by 2050 and is engaged in a variety of research and development activities.

Overview of Ocean Clean Energy Business

MOL has establishedMOL Group Environmental Vision 2.2and has already taken steps to reduce GHG emissions. In 2022, SHOFU MARU, a vessel equipped with Wind Challenger sails which use wind as auxiliary propulsion, was delivered and started her operation.

Wind Challenger sails are state-of-the-art “rigid sails” covered with FRP (Fiber Reinforced Plastic), hard material and can efficiently convert wind power into propulsion.

The ratio of fuel consumption reduction is depended on the wind direction and wind force on the vessel's route, it can reduce fuel consumption by 5-8% in average.

GHG Reduction and Ship Fuel Composition Scenarios

As a key action towards achieving substantial net zero greenhouse gas (GHG)emissions by 2050 and promoting sustainable development for people, society and the planet, MOL aims to achieve the "Green Ocean Shift" by contributing to construct clean energy supply chain from upstream to downstream.

WIND HUNTER

~Green hydrogen production plant on the sea~

Wind Hunter, it is a vessel which aims to leverage the sail technology that MOL nurtured in Wind Challenger project and applies more advanced technology to create, store, and transport green hydrogen produced by infinite offshore wind. In other words, it is a hybrid plant that combines a moving offshore wind turbine and a hydrogen production facility.

The wind energy captured by the sails is used to propel Wind Hunter, and hydrogen is produced by generating electricity in underwater generator turbine. The project also aims to supply the hydrogen energy to the land usages, and to achieve complete zero emissions.

Producing Hydrogen

Wind Hunter sails using wind energy, while at the same time generating electricity by underwater turbine. By electrolyzing pure water made from seawater, it produces hydrogen.

By causing a chemical reaction of hydrogen and toluene, it creates Methylcyclohexane: MCH, which is one of the hydrogen carriers, and stores that in MCH tanks onboard.

During high winds, Wind Hunter produces hydrogen by extending its sails to capture the wind while it uses offshore wind power to navigate.

When sailing in weak windy waters or when entering/leaving port, the sails are retracted, and the propellers are rotated to propel the vessel using the electric power (*) obtained under high winds.

*The power is stored in the battery during high winds.

Why MCH?

Hydrogen generated onboard is gas condition. To convert hydrogen to liquid hydrogen, for example, requires tremendous energy for its conversion into a low temperature of minus 253°C. This also requires high level of safety measures. It is very important to find an efficient, economical, and safe way to store and transport hydrogen created by offshore wind power.

MCH, one of the hydrogen carriers, has the following features.

(1) Easy to handle because it is liquid at ambient temperature and pressure.

(2) Efficient and safe for storage and transportation of hydrogen.

(3) Current gasoline infrastructure can be used for it.

Deliver Hydrogen

As Wind Hunter approaches a harbor, the vessel folds down the sails and navigates using propulsion propellers.

In the following slides, you can see how the lines are connected to the hull with the support of several drones that fly off from inside the vessel after the vessel has docked, and then MCH is discharged.

After the discharging operation is completed, the vessel is replenished with toluene and the vessel is once again ready to set sail on the next voyage.

World's 1st Successful Onshore Supply of Green Hydrogen Produced at Sea - the demonstration yacht "Winz Maru"

In March 2025, green hydrogen produced from offshore wind using the demonstration yacht "Winz Maru" was supplied onshore in the central breakwater area of Tokyo in the "Prior Project at Tokyo Bay eSG Project”, collaboration with the Tokyo Metropolitan Government". This project has been started since 2023.

This marks the first time in the world that a ship has supplied green hydrogen, produced on its own while underway, for use on shore.

Utilize Hydrogen

WIND HUNTER an option “unmanned solution” in the future, can be sail and supply energy not only to nearby ports in large cities but also to rural areas and remote islands, taking advantage of the ship as a mobility advantage. This technology enables the production and supply of hydrogen using ships at locations where hydrogen is in demand.

MOL aims create hydrogen supply chains to employ such technologies and would need further collaborations with various parties and stakeholders to achieve strong enough for the future.

From Imagination to Creation, MOL is taking on the challenge of realizing WIND HUNTER.

Related Press Releases

- Sep 19, 2025

- Jun 3, 2025

- Mar 7, 2025

- Oct 4, 2023

Download Materials

Wind Challenger Service Overview

download materials about outlines the Wind Challenger, including its structure and how it is propelled by wind.

Initiatives to realize MOL group Environmental Vision 2.2

Download MOL’s initiatives on the Environment.

We will further enhance our activities to reduce environmental impact as an Environmentally Advanced Company.

WIND HUNER White Paper

”WIND HUNTER” project, a zero-emission project utilizing wind power and hydrogen. A document outlining this project is available for download.

WIND HUNTER project will contribute to the creation of a green hydrogen supply chain and a decarbonized society.

Related Case Studies

-

WIND CHALLENGER Delivered the First vessel

Wind ChallengerMitsui O.S.K. Lines, Ltd. (MOL) has developed the Wind Challenger, which converts wind energy directly to a vessel propulsion force. As a part of this project, the hard sail system to be installed on the first Wind Challenger ship was finally completed in February 2022.

-

WIND CHALLENGER Sea Trial

Wind ChallengerMitsui O.S.K. Lines, Ltd. (MOL) has developed the Wind Challenger, which converts wind energy directly to a vessel propulsion force. As a part of this project, the hard sail system to be installed on the first Wind Challenger ship was finally completed in February 2022.

-

WIND CHALLENGER Hard Sail Completed

Wind ChallengerThe hard sail system to be installed on the first Wind Challenger ship was finally completed.

-

DELIVERY OF 1ST WIND CHALLENGER

Wind ChallengerAs part of our greenhouse gas (GHG) emission reduction project, the first Wind Challenger is scheduled for completion.

BLOG

-

.png)

Wind Hunter Project Enters a New Scene -Initiating Technological Research to Build a Hydrogen Supply Chain-

EnergyEco Friendly -

The Time Will Come When Even the Latest Built Vessels Will Have Sails: Wind Challenger (Part 3)

EnergyGeneral Shipping -

The Time Will Come When Even the Latest Built Vessels Will Have Sails: Wind Challenger (Part 2)

EnergyGeneral Shipping -

The Time Will Come When Even the Latest Built Vessels Will Have Sails: Wind Challenger (Part 1)

EnergyGeneral Shipping -

Wind power, the leading natural energy resource!

Eco Friendly

Related Solutions and Services

WIND CHALLENGER

Mitsui O.S.K. Lines, Ltd. has developed the Wind Challenger, which converts wind energy directly to a vessel propulsion force through an extensive use of the latest technologies. Wind energy is clean and unlimited. We aim to drastically reduce greenhouse gas emissions by converting wind energy to propulsion force for ships. In October 2022, the 1st vessel, “SHOFU MARU” was delivered and started operation.

Related Contents

Contact

- Top

- LOW-CARBON / DECARBONIZED BUSINESS

- WIND HUNTER Green hydrogen producing vessel