BLOG

Report from the Captain of MOL FSRU Challenger

- Energy

2020.12.28

This time, we would like to introduce captain’s report of the world’s largest FSRU “MOL FSRU Challenger”, which is now operating in Turkey.

Why FSRU?

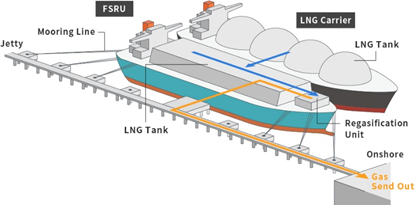

An FSRU is a specialized Liquefied Natural Gas (LNG) ship that has an on-board regasification plant capable of returning LNG back into a gaseous state and then supplying it directly into the gas network ashore. It is used to import LNG which is mainly used for heating and power generation and is a cheaper and quicker solution than a land-based facility.

The timing and volume of LNG imported can be adjusted to meet market needs. Importantly, importing LNG by ship allows to access the international gas supply market, providing stability of supply.

“MOL FSRU Challenger” – operating at BOTAS Dortyol Terminal

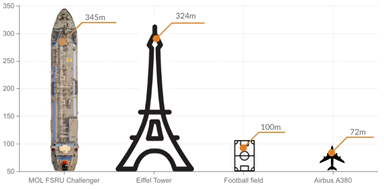

The world’s largest specialized ship to import LNG, the MOL FSRU Challenger, longer than the Eiffel Tower, is engaged in operations at BOTAS Dortyol terminal in Iskenderun bay, Turkey since 2017, to meet Turkey’s booming gas demand for domestic and industrial consumers.

(MOL FSRU Challenger is longer than Eiffel Tower.)

The 345-meter (1,132 feet) tanker can store 263,000 cubic meters of LNG, enough to supply power to a city of more than 70,000 homes for a year.

Overview of FSRU operation

As a result of this continued regasification activity on the world's largest FSRU, the on-board LNG inventory is steadily decreasing until the arrival of the next LNG ship interrupts the decline.

Loading of the new cargo is carried out from an incoming LNG ship onto MOL FSRU Challenger via the sea-side while MOL FSRU Challenger remains moored alongside jetty. It is a cargo transfer between two seagoing ships positioned alongside each other.

(Allocation of Jetty, FSRU and LNG Carrier)

Importance of mooring and hose connection between FSRU and LNG Carrier

Six fenders are arranged and secured on the FSRU seaside to prevent contact between the LNG ship and MOL FSRU Challenger. The MOL FSRU Challenger is equipped with mooring arrangements which allows for safe mooring configuration of any sized LNG ship. Mooring and cargo hoses connection are carried out by the FSRU personnel with the assistance of the LNG ship crew, local pilots and port tugs. It is an operation that demands the best of seamanship and professional skills from all teams involved. As the person in overall command, I feel the strength of the team, when a proper coordinated operation has been performed, based on well established procedures and communications protocols, and when all the members efficiently execute the operation for the satisfaction of all parties.

A stand-by tug will remain nearby the LNG ship in addition to a local pilot on board, for the entire stay of the shipalongside MOL FSRU Challenger.

(Fenders being arranged between FSRU and LNG carrier. Mooring and hose connection requires the best seamanship and professional skills from all teams involved)

Safety measures on loading LNG to FSRU

LNG transfer commences once all safety tests and checks are carried out, including for the cargo hose connections, with the minimum flow ramping up until the desired flow is achieved, as agreed during the pre-operational meeting. Even during ship to ship LNG cargo transfers, the FSRU gas send out ashore remains fully operative and it is not affected by ongoing transfer of LNG, as the specific design of the FSRU allows it to do so.

(the hoses are frozen due to about -162◦C of LNG)

A team of experienced and skilled deck officers and engineers constantly monitor the progress of the simultaneous operations supported by both ship’s crew attending on watches in tandem with ashore side operators on duty in the jetty facility control room.

(Picking up the mooring rope after Ship to Ship)

Ship To Ship operation is uneventfully completed when LNG ship completes his departure maneuvering with MFC deck hands assistance to release her mooring lines.

The MOL FSRU Challenger team then estimate when the next cargo will be received based on the customer’s demand of gas over the upcoming days and weeks.

You can get other case studies of FSRU projects handled by Mitsui O.S.K. Lines (MOL) in various areas of the world, click the following!

Writer:Captain Angel Maruri

Sailing on LNG ships since 1996, I joined MOL LNG Transport (Europe) Ltd. in 2005 as Chief Mate. In 2008 I was promoted to Captain position and ever since served on different trades and LNG ships type within the company. As a man in his 50s, a commitment for health translates into a restricted number of visits to mess room and daily exercising.

Recommended Articles

2022.07.05

- General Shipping

2021.04.13

- Energy

2025.03.18

- General Shipping

2021.08.07

- Eco Friendly

Latest Articles

2026.01.20

- Eco Friendly

- General Shipping

2025.12.09

- Eco Friendly

- General Shipping

2025.12.03

- General Shipping