BLOG

The Time Will Come When Even the Latest Built Vessels Will Have Sails: Wind Challenger (Part 1)

- Energy

- General Shipping

2024.03.19

At COP28, held in Dubai, the United Arab Emirates (UAE), from 30th November to 12th December last year, MOL was the only shipping company to exhibit at the Japan Pavilion hosted by the Ministry of the Environment. We showcased our technology, services, and efforts against climate change to the World. Under the theme of “Utilizing wind power technology on ships”, we displayed the next-generation wind-assisted vessel, “Wind Challenger”, and the green hydrogen-producing vessel "Wind Hunter", and received significant interest from numerous visitors to the pavilion and various stakeholders.

Please click here for the report of COP28 → COP28: Review of MOL's participation

This time, we will focus on the "Wind Challenger”, will be released in three parts, which will include interviews with the developers, their thoughts, and future prospects for this project.

Towards a New Age Where "Vessels with Sails become the Norm"

One year has passed since the launch of the world’s first MOL commercial vessel, the “Shofu Maru”, equipped with the telescopic hard wing sail “Wind Challenger”. This innovation raises questions: how does it differ from traditional sails, and is it effectively reducing GHG emissions as intended?

The developers are already looking ahead to a time when vessels with sails become the norm.

A large hard sail that reduces GHG emissions about 8% on the Japan-North America West Coast Route

The most primitive but most reliable form of propulsion for vessels is the wind

There is no precise record of when humanity first harnessed wind power of sailing, but the idea of the “sail” has been revolutionary. While modern commercial ships evolved into forms that don’t require sails, Kensuke Mizumoto from MOL says: "My greatest wish is for our children's generation to say that 'Vessels without sails are outdated'."

A sailing ship that turns wind to propulsion

A sailing ship that turns wind to propulsion

Mizumoto, who is a Senior Coordinator in the Technology Development Planning Team at the Technical Division, has been involved in developing the “Wind Challenger” project, a wind propulsion system using a variable rigid sail, which MOL has been developing with partner companies as a technology to reduce GHG emissions by vessels. The development of the telescopic hard sail is a first in the world.

The commercial vessel “Shofu Maru”, equipped with the Wind Challenger, marked its first year of operation in October 2023.The Shofu Maru was also selected as the "Ship of the Year 2022" by the Japan Society of Naval Architects and Ocean Engineers (JASNAOE). The selection committee praised this achievement, highlighting the re-emergence and successful practical application of wind-powered cargo vessels, particularly in the context of global environmental conservation.

Kensuke Mizumoto, Technology Development Planning Team, Technical Division

Kensuke Mizumoto, Technology Development Planning Team, Technical Division

The first commercial vessel "Shofu Maru" equipped with Wind Challenger

The first commercial vessel "Shofu Maru" equipped with Wind Challenger

A closer look at the Shofu Maru reveals a bulk carrier operated by MOL, with a length of approximately 235 meters (approx. 771 ft), a width of 43 meters (approx. 141 ft), and a maximum draft of about 13 meters (approx. 43 ft). The vessel is powered by a diesel engine and weighs about 50,000 tons. It can carry about 100,000 tons of coal, enough to operate a 1 million kilowatt thermal power station for about half a month.

It was constructed at the Oshima Shipbuilding Co., Ltd. in Nagasaki Prefecture and is chartered by Tohoku Electric Power Co., Inc., transports coal between Japan and countries like Australia, Canada, Indonesia, South Africa, completing six voyages as of December 18th and currently heading to Australia again.

Crescent-shaped sail that has 4-Stages, is 53 meters high and 15 meters wide

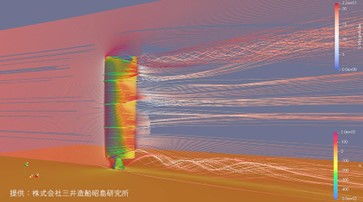

Equipped at its bow with the Wind Challenger, the Shofu Maru features a unique four-stage, telescopic, crescent-shaped sail. At its maximum extension, the sail reaches a height of 53m (approx. 174 ft) and a width of 15m (approx. 49 ft). The cross-section is crescent-shaped, and the total surface area is approximately 800 square meters when fully expanded. The inside of the sail is hollow, and the surface is covered with a lightweight, sturdy material to maintain strength while minimizing weight. This sail can compact to 23 meters (approx. 75 ft) in height, facilitated by internal spars (supporting poles).

Assuming that the height of one floor of an office building is 3 meters (approx. 9 ft), a height of 53 meters (approx. 174 ft) is equivalent to a huge building of 18 floors. The expansion and contraction are achieved by use of a spar inside the sail, which is elastic.

The sail is extremely robust. Yoichi Wakabayashi, who has been in charge of the technical development of the Wind Challenger as a Senior Coordinator of the Zero-Emission Technology Innovation Team of the Technical Division of MOL, says, "In its folded state, the sail can withstand strong winds over 50 meters (approx. 164 ft) per second. Sensors at the base of the spars that extend and retract the sail continuously measure strain and overall load changes, automatically controlling the expansion and contraction of the sail".

Yoichi Wakabayashi, Zero-Emission Technology Innovation Team, Technical Division

Yoichi Wakabayashi, Zero-Emission Technology Innovation Team, Technical Division

Wind Challenger with a unique shape different from the sails of previous sailing vessels

Wind Challenger with a unique shape different from the sails of previous sailing vessels

This sails captures the wind to propel the ship, achieving energy savings, and can reduce GHG emissions by about 5% on routes from Japan to the east coast of Australia, and about 8% on routes from Japan to the west coast of North America.

While a 5-8% reduction may seem modest, it is significant for a large commercial vessel like the Shofu Maru, which consumes 10 tons of fuel (C heavy oil) per day. A few percent reduction in GHG for a large commercial vessel implies substantial savings in heavy oil consumption. If heavy oil consumption could be reduced by 1 ton per day, CO2 emissions could be reduced by about 3 tons. In addition, the Wind Challenger’s design allows for its use regardless of the type of engine or fuel, including future transitions to ammonia or hydrogen. This flexibility is a distinctive feature of the Wind Challenger.

"People in the industry were surprised when we said we could achieve a 5-8% reduction, but we have that much confidence in this system," says Kensuke Mizumoto, sub-team leader at MOL's Technical Development Planning Team. "In fact, our voyages so far have nearly matched our simulations in terms of GHG reduction.". (Mizumoto)

Source: Akishima Laboratory Inc.

Source: Akishima Laboratory Inc.

Wind Challenger, which is 53 meters (approx. 174 ft) high and 15 meters (approx. 49 ft) wide, freely expands and rotates to catch the wind and propel the ship forward. However, wouldn't such a large "structure" at the bow disrupt the ship’s balance?

Wakabayashi reassures us such worries are misplaced and explains: "Bulk carriers are vessels with high stability due to their structure, and the total weight of Shofu Maru loaded with coal can be as much as 150,000 tons. Compared to that, the structure of the Wind Challenger is extremely light and wouldn’t affect the balance of the ship".

In the first part, we have mainly focused on the rigid sail, Wind Challenger. Please read the next installment: “The Time Will Come When Even the Latest Vessels Have Sails: Wind Challenger (Part 2)"

The Time Will Come When Even the Latest Built Vessels Will Have Sails: Wind Challenger (Part 2)

The Time Will Come When Even the Latest Built Vessels Will Have Sails: Wind Challenger (Part 3)

Recommended Articles

2022.07.05

- General Shipping

2021.04.13

- Energy

2025.03.18

- General Shipping

2021.08.07

- Eco Friendly

Latest Articles

2026.01.20

- Eco Friendly

- General Shipping

2025.12.09

- Eco Friendly

- General Shipping

2025.12.03

- General Shipping

- BLOG

- The Time Will Come When Even the Latest Built Vessels Will Have Sails: Wind Challenger (Part 1)